Case Studies

Case Study – Sealant Tape Inspection

Our Client

Our client is a leading manufacturer of sealing, bonding and coating solutions for a wide range of uses in the construction and manufacturing industries. This project focused on the production processes for their butyl-based weather sealant tape product which is used for lap sealing between glass panels across a variety of applications. The tape is produced in various lengths from 50ft to 300ft in 8 strands on a single roll. We provide our statistical process control software to identify any problem.

The Challenge

Current quality control processes rely on a traditional process of manual inspection across random samples of the product as it leaves the production line. Production volumes are very large which makes it almost impossible to carry out a thorough check which is robust enough that the firm can be confident every product meets their exacting standards.

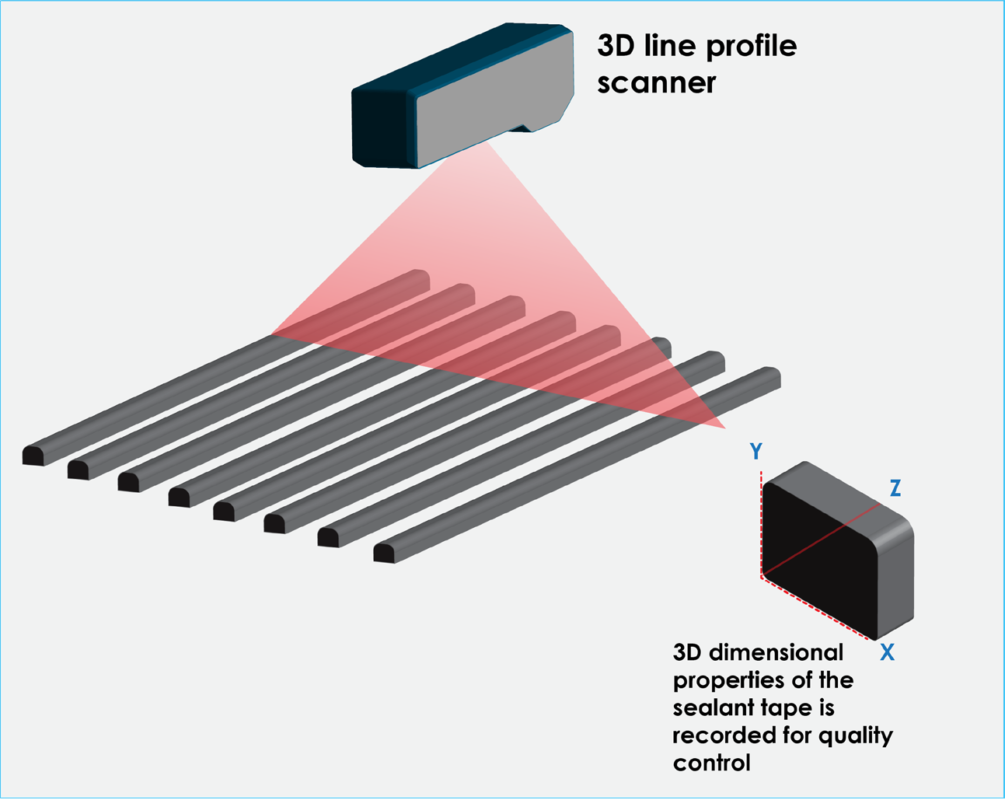

The quality control process looks at the height and width of the tape that is produced in the upstream process as any deviation from production standards could result in a product which is unable to deliver adequate sealing when it is used by customers. This would potentially lead to unwanted moisture ingress within the application of the product which could then lead to damage to the structures and products where the tape has been applied. Excessive height of the tape may also, in low tolerance applications, cause uneven pressure on the joint where it is used, leading to early product or structural failure.

The Solution

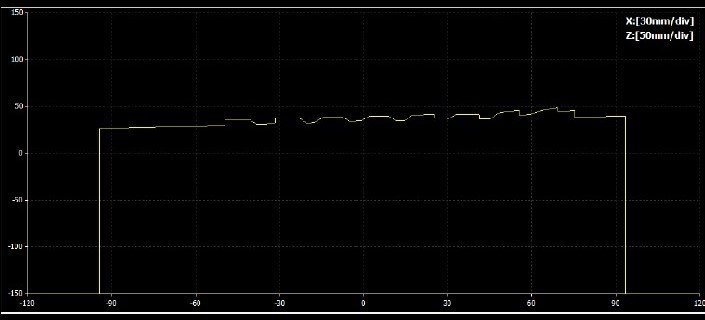

The solution uses a 3D vision sensor mounted on a fixed gantry within the upstream production process. The sensor scans all 8 strands of the butyl tape and continually measures the height and width of the product as it passes along the production line, enabling 100% real time inline inspection.

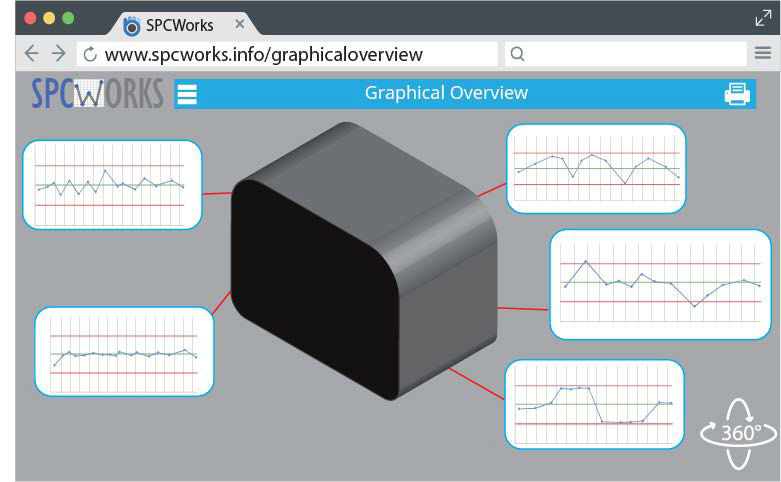

Data from this process is recorded within Unblink3D real-time data intelligence software SPCWorks and saved to a Microsoft SQL database. When the software identifies a problem with the tape which falls outside the acceptable parameters, the machine is automatically stopped.

The Results

The SPCWorks software is able to display the measurements recorded by the 3D Sensor in a graphical format for quality assurance staff to review. This provides an opportunity to oversee a far greater proportion of the overall production volume compared to traditional methods.

Statistics (Cp, Cpk, Pp, Ppk) which also provide complete visibility of the upstream production process, enabling our client to take preventative measures before a defect occurs, and where there are problems, the tape can be removed from the production line.

These new processes ensure that no defective tape is packaged or sold to the end consumer resulting in no in-operation product defects using statistical process control software.