Case Studies

Case Study – EV Battery Tray

Our Client

Our client is planning to produce electric vehicle (EV) battery trays for a high-performance electric vehicle. These highly engineered components play a critical role in vehicle safety, rigidity, and weight. EV battery tray and weld inspection can be be handle via Unblnk3D software and solution.

Unblink3D software products ensure any defects are identified at an early stage

As a result, they require over 500 rivets and more than 100 welds. With an anticipated production volume of 65,000+ annually, the inspection cycle for each tray must be completed in less than 200 seconds.

The Challenge

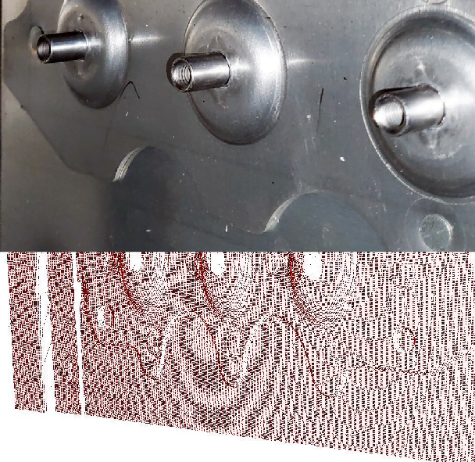

The battery tray is 4 meters long and 1.5 meters wide and contains several hundred features – including important welds that need to be completed without any defects before adhesive sealants are applied.

To guarantee structural integrity, over 100 welds must be inspected. Afterwards, more than 500 clinched sheet metal rivets need to be checked at 0.1mm accuracy, because the height of the raised round rivets determines how much pressure must be applied when the sheets are joined. Finally, various holes, slots, and mounts need to be inspected to comply with GD&T specifications – ensuring the correct fittings and alignments of hundreds of battery cells prior to final assembly.

The Solution – EV Battery Tray and Weld Inspection

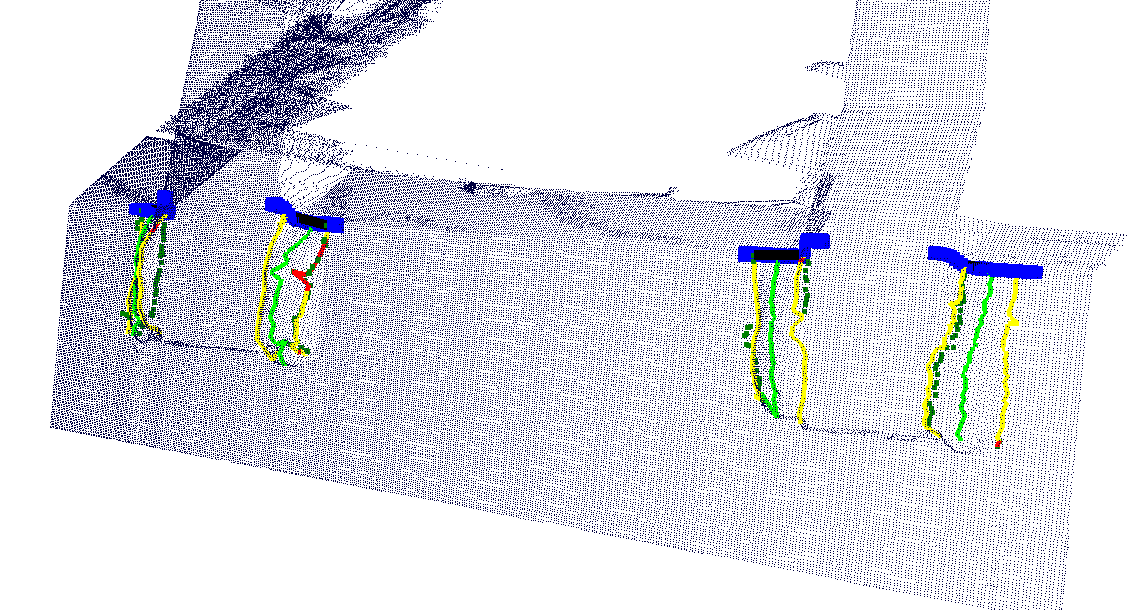

Unblink3D software solution combined with two FANUC robots and two laser profile cameras, implements integrated 100% inline 3D vision inspection that can continually monitor production quality. Unblink3D industrial engine and communications software, comXtream, was deployed to manage communication between the different devices. As the robots carry out high-speed inspection on all the critical

features, the results are recorded, and our 3D processing software, ScanXtream analyzed the 3D point cloud of the clips and connectors to check for various types of defects.

The Results

Unblink3D software’s powerful functions enabled manufacturers to build up a high-performance inspection system that provides a complete solution analyzing each of the battery tray’s critical features. This ensures that every component is defect-free when it reaches the end user and that it will last the vehicle’s lifetime. All of this is achieved in under 200 seconds.